involute gear

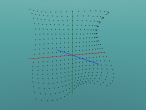

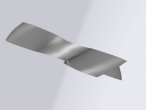

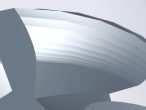

It turned out that producing a set of involute gears requires quite a bit of geometry in addition to involutes.

It is useful to get familiar with gear terminology and with the special properties of an involute of a circle. In particular, it is necessary to figure the angular width of a tooth at the base circle which is where the involute, curved section of a tooth begins.

So there is a lot to explain in this logo program.

Next steps include to figure out why there is a slight overlap between teeth from both gears, and to make the gears 3d with some depth. Is there a way to use the extrusion functionality of x3d ?

[Update: the initial configuration was slightly off. Scene and logo updated.]

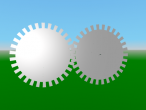

Well, here is the logo:

- aplesch's blog

- Login or register to post comments

- 26705 reads

Comments

gear ratio

Yes, it should be possible to produce any standard involute gear. Gears fit together if they same pitch.

The velocity of the gear rotations needs to be inversely proportional the pitch radius. It is easiest to think about wheels instead. For a unit period of time both wheels need to cover the same distance on their circumference.

Good point about the possible lack of synchronization for the spinning of the gears. I will try to use just one time sensor, so both orientation interpolator should get the same input.

TimeSensor

Another way to do can be changing the startTime of the TimeSensors (if two). TimeSensor is fully implemented in X3DOM. The fields startTime and stopTime etc. will not show in DOM but I remembered the SET command can still get it to work.